Cooka Technology:

Production - From Prototype to Full-Scale Manufacturing

At Cooka Technology, we understand that your production needs can vary greatly depending on the stage of your project. We offer a comprehensive production service designed to be highly flexible, responsive, and easily scalable to meet your specific requirements – whether you need a single prototype, a pilot run, or full-scale manufacturing.

Transforming Your Designs into

Precision Plastic Parts

Our state-of-the-art facilities and experienced team are dedicated to delivering:

Unmatched Precision

Our advanced molding machines and rigorous quality control processes ensure your parts meet exact specifications, every time.

Diverse Material Selection

We offer a wide range of plastic materials to suit your specific needs, from cost-effective options to high-performance engineering resins.

Efficient Production

Our streamlined processes and optimized manufacturing techniques ensure fast turnaround times and cost-effective production for both low and high-volume orders.

Design for Manufacturability (DFM) Support

Our team can collaborate with you to optimize your design for the injection molding process, maximizing efficiency and minimizing potential issues.

The Cooka Technology Plastic Injection

Molding Advantage

One-Stop Shop

We handle the entire process, from mold design and development to high-volume production, streamlining your project experience.

Quality Assurance

We are committed to the highest quality standards, with rigorous inspections and testing procedures throughout the manufacturing process.

Global Manufacturing & Support

With a global network of facilities, we offer efficient production and reliable support wherever you are located.

Sustainable Practices

We are committed to environmentally responsible manufacturing practices, using energy-efficient technologies and exploring the use of recycled materials.

A Wide Range of Applications

Plastic injection molding is a versatile process used in countless industries. Cooka Technology is proud to provide high-quality injection molded components for applications such as:

Automotive

Interior and exterior components, engine parts, and electrical housings.

Consumer Electronics

Mobile device casings, appliance parts, and electronic housings.

Medical Devices

Sterile housings, disposable components, and medical equipment parts

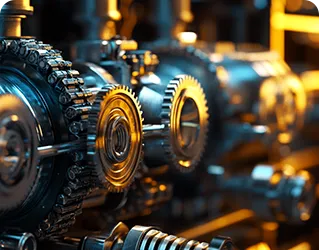

Industrial Equipment

Gears, housings, and functional components for various machinery.

And More: The possibilities are endless! We can create plastic injection molded components for virtually any application.

Hello! What do you need help with?